Zinc selenide (ZnSe) materials exhibit excellent light transmittance across a broad wavelength range (0.5μm to 22μm). They are commonly used as substrate materials for mirrors and beam splitters in high-power CO₂ laser systems. Additionally, their superior refractive index uniformity and consistency make them ideal for applications such as windows and lenses in thermal imaging systems, medical devices, industrial thermal radiation meters, and infrared spectrometers.

Item No :

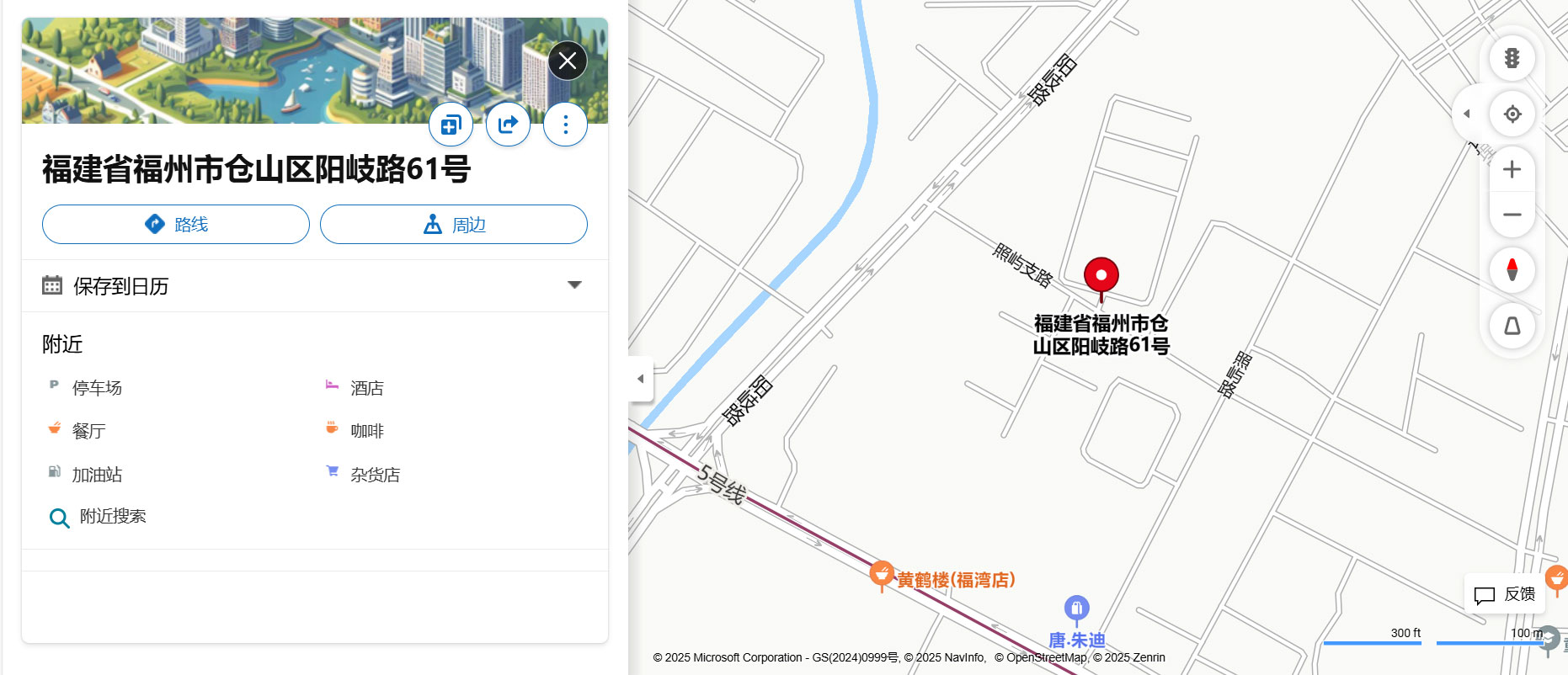

ZnSe WindowsProduct Origin :

FuZhouProperties:

| Crystal Structure | Cubic/Polycrystalline |

| Crystallite Size (Diameter) | <100μm |

| Density (g/cm³) | 5.27 |

| Resistivity (Ω・cm) | >1012 |

| Chemical Purity (%) | 99.9996 |

| Refractive Index Inhomogeneity @632.8nm | <3×10-6 |

| Bulk Absorption Coefficient @10.6μm | <0.0005cm-1 |

| Thermo - optic Coefficient (dn/dT) @10.6μm | 6.1×10-5/℃ |

Standard Products:

| Size Specification | Profile Precision | Surface Form Precision | Parallelism Precision | Coating Wavelength Band |

| 10-100mm | ±0.05mm | λ/6@632.8nm | 10 arcseconds | 400-700nm,700-1100nm |

Why choose Zinc selenide (ZnSe) windows?

Zinc selenide (ZnSe) windows are favored for their high transmission across 0.6-16 μm (notably 8-14 μm LWIR), low dispersion, and thermal stability. With a moderate refractive index (n≈2.4@10 μm), they enable chromatic aberration correction in optical systems. Featuring high laser damage threshold, they suit CO₂ laser (10.6 μm) windows, IR imaging lenses, and spectrometer prisms. Though softer (Mohs ~2.5), ZnSe outperforms germanium in moisture resistance for humid environments.