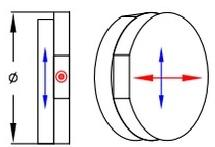

Cemented Zero Order Waveplate is constructed by two quartz plates with their fast axis crossed, the two plates are cemented by UV epoxy. The difference in thickness between the two plates determines the retardation. Zero order waveplates offer a substantially lower dependence on temperature and wavelength change than multi order waveplates.

|

Features: Cemented by Epoxy Thickness 1.5~2mm Double Retardation Plates Broad Spectral Bandwidth Wide Temperature bandwidth |

|

Item No :

WPCProduct Origin :

FuZhouSpecifications:

|

Material:

|

Quartz

|

|

Diameter Tolerance:

|

+0.0, -0.1mm

|

|

Wavefront Distortion :

|

λ/8 @ 632.8nm

|

|

Retardation Tolerance:

|

λ/300

|

|

Parallelism:

|

<1 arc second

|

|

Surface Quality:

|

20/10

|

|

Clear Aperture:

|

>90%

|

|

Coating:

|

S1&S2: R<0.2% @ wavelength

|

|

Standard wavelength:

|

266nm, 355nm,532nm, 632.8nm, 780nm,808nm, 850nm, 980nm,1064nm, 1310nm, 1480nm, 1550nm

|

Standard Products:

|

Half Waveplates P/N#

|

Quarter Waveplates P/N#

|

Diameter(mm)

|

|

WPC210

|

WPC410

|

10.0

|

|

WPC212

|

WPC412

|

12.7

|

|

WPC215

|

WPC415

|

15.0

|

|

WPC220

|

WPC420

|

20.0

|

|

WPC225

|

WPC425

|

25.4

|

|

WPC230

|

WPC430

|

30.0

|

Technical Advantages of Cemented Zero-Order Waveplate:

The cemented zero-order waveplate realizes zero-order phase retardation by laminating birefringent materials with optical adhesive, boasting notable technical advantages: a low-dispersion design ensures phase retardation error <5% across a 400-2000nm broad spectral range, with precision reaching λ/100 level. Its cemented structure enhances mechanical stability, supporting operation across a wide temperature range of -20℃ to 80℃, while maintaining a laser damage threshold >5 J/cm² (at 1064nm). In fiber-optic communication WDM systems, it synchronously stabilizes the polarization states of 1310/1550nm dual wavelengths, reducing polarization-dependent loss (PDL) to below 0.3dB. In femtosecond laser micro-nano processing, its low-dispersion characteristics prevent polarization state drift of pulsed light, ensuring polarization precision of ±0.1° for 800nm laser and facilitating improved repeatability and resolution of micrometer-scale processing linewidth.